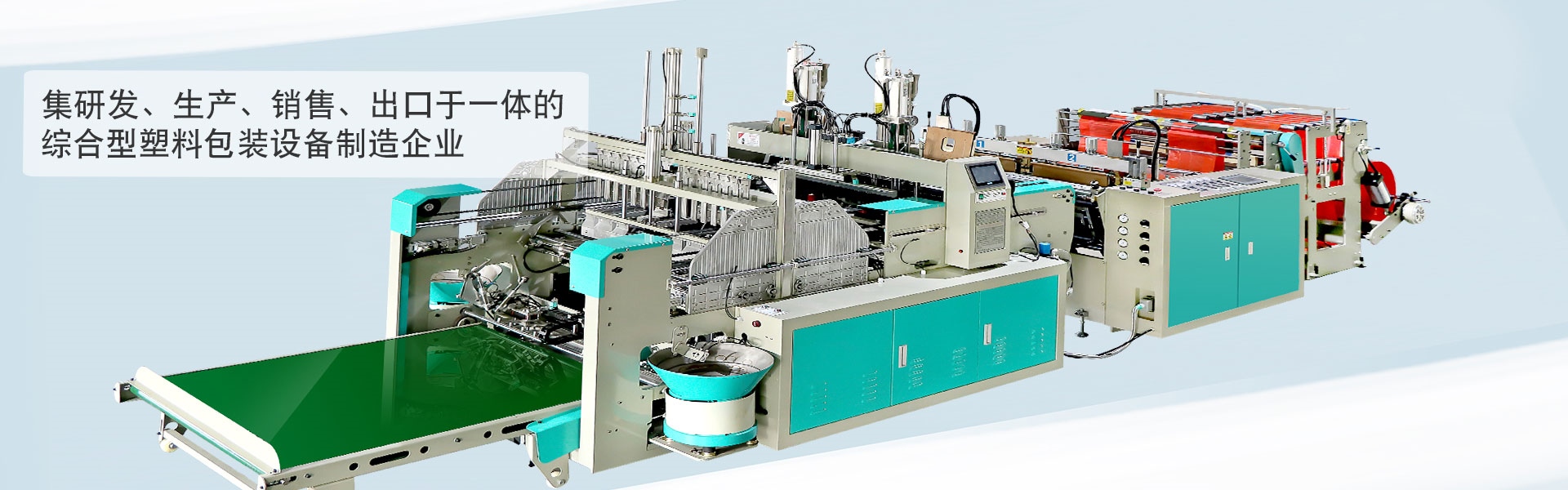

Rolling bag making machine manufacturer Anhui Yinsheng Electrical Equipment Co., Ltd. will share with you the development history and status of China's bag making machine:

In recent years, although the annual growth rate of China's packaging industry ranks first in the traditional industry, in order to integrate with the international market, it is necessary to accelerate the development of packaging technology to make it develop in an economic, efficient, and multifunctional direction. As an important member of the packaging machinery industry, bag making machines are developing rapidly in China. In recent years, in addition to the demand of the video industry, the demand for automation in the industry is also rising. At present, there is huge room for development in China.

The development history and current situation of China's bag making machine China's bag making machine has only 20 years of history from research and development, application to development. It is based on the introduction of Japanese equipment and digestion and absorption through PCB copy board. From the initial stage, it can only produce 400 It is a bag making machine with a width of millimeters and a speed of only 20 meters per minute. Until now, it has been able to produce bag making machines with a speed of 150 meters per minute and a width of less than 1,000 mm, and various automatic bag making machines with more than 100 segments per minute. Provide a lot of equipment for the development of domestic flexible packaging industry. However, in recent years, with the increase in demand, China still needs to import a large number of imported bag making machines from Japan and other places. This also means that there is a large gap between our bag making machines and advanced foreign countries.

Characteristics and competition of bag making machines. Looking at the competition of the most advanced and fully automated middle-sealing bag making equipment at home and abroad, the most important is the competition of equipment working efficiency, that is, the competition of high-speed and high-efficiency features. The equipment used in flexible packaging bag making machines is a combination of machine, electricity, light and gas. High mechanization and automation are important directions for its development. It requires high-speed and high-efficiency to reduce the cost calculation of target products, and requires high flexibility and flexibility to suit the update and change of target products. Therefore, when choosing the target of copying board for flexible packaging bag making equipment, high-speed and high-efficiency should be taken as a reference, and on this basis, PCB modification, secondary development and upgrade of software and hardware should be carried out to improve equipment competitiveness.

Bottlenecks and priorities of PCB making of bag-making machines However, at present, various technical parameters of advanced equipment for domestic and international full-seal automatic bag-making machines are almost the same, and the main difference in this type of equipment in China is in the speed of the whole machine. However, there is not much room for simply increasing the operating speed of the equipment to improve the efficiency of the equipment. The most advanced equipment stays at the speed of 12000P per hour, which has become a bottleneck for the performance of the equipment.

Therefore, the focus of the current research on the PCB modification of plastic bag making machines is not just to increase the speed of the equipment, but to improve the equipment's working efficiency by modifying the single-line bag-making mode of the equipment, etc., so that the equipment can maintain higher speed and efficiency. And full-automatic high-speed middle-sealing full-automatic bag-making machine equipment for industrial production and promotion.

Related Industry Knowledge

- Sealing and cutting machine manufacturers share with you how to properly use the sealing and cutting machine

- Computer hardware troubleshooting for vest bag automatic bagging machine

- Convenient bag making machine manufacturers tell you the common faults of bag making machine

- High-speed continuous roll bag machine swing mechanism

- Convenient bag making machine manufacturers tell you the detailed process of bag making machine bag

- Punching device of full automatic continuous bag rolling machine

- T-shirt bag making machine manufacturers tell you the characteristics of T-shirt bag making machine

- Punching device of fully automatic ultra-high speed bag making machine

- Yinsheng Electric shares with you the performance characteristics of heat sealing and cutting bag making machine

- Yinsheng share with you how to improve heat seal strength in bag making machine