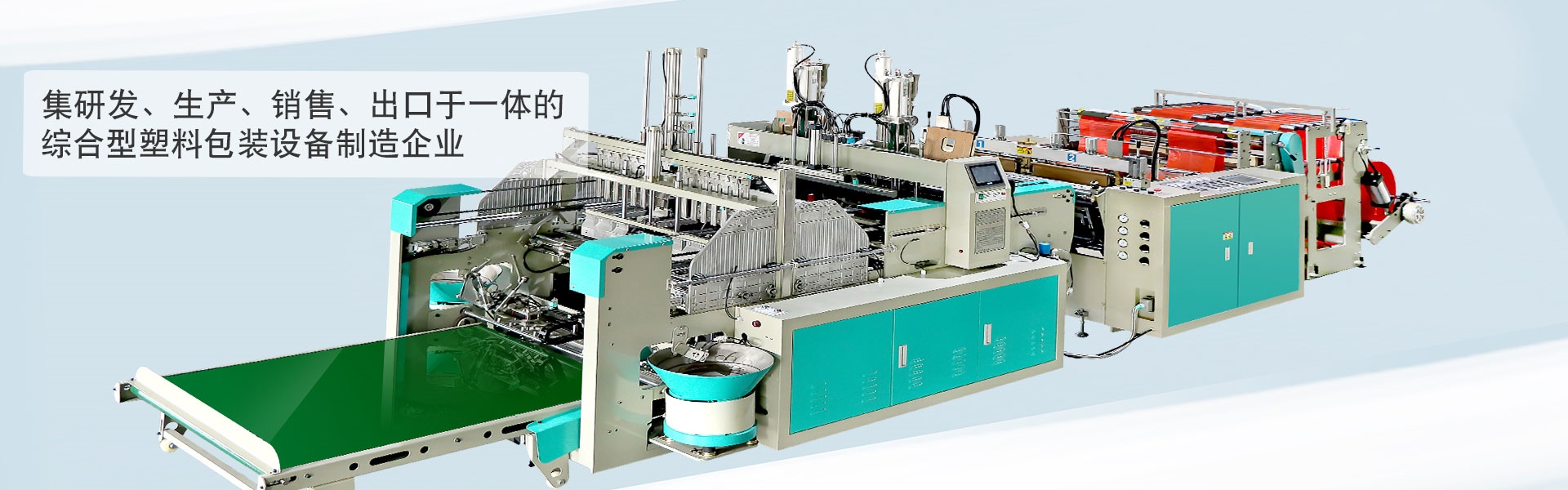

High Speed Linkage Bag On Roll Machine

The high-speed continuous roll bag machine manufacturers share with you the main bag making functions of the bag making machine as follows: The bag making machine can produce various types of bags for the food and beverage, pharmaceutical and FMCG industries. Typically, these machines are fully automated, only supplementing the source material

The high-speed continuous roll bag machine manufacturers share with you the main bag making functions of the bag making machine as follows:

The bag making machine can produce bags for all kinds of goods in the food and beverage, pharmaceutical and FMCG industries. Normally, such machines are fully automated and require operator intervention only when replenishing the source material and removing the molded product.

The bag making process usually has several main functions, including material feeding, sealing, cutting, and bagging.

In the feeding section, the flexible packaging film fed by the roller is unwound through a feeding roller. The feed roller is used to move the film within the machine to perform the required operation. Feeding is usually a batch operation, and other operations such as sealing, cutting, etc. are performed during the feeding stop. Dancing rollers are used to maintain a constant tension on the film roll. To maintain tension and critical feeding accuracy, feeders and dancing rollers are required.

In the sealing section, the temperature-controlled sealing element is moved to contact the film for a specific period of time in order to properly seal the material. Sealing temperature and sealing time vary depending on the type of material and need to be constant at different machine speeds. The configuration of the sealing elements and the associated machine format depends on the type of seal specified by the bag design. In most forms of machine operation, the sealing process is accompanied by a cutting process, and both operations are performed when the feed is complete.

During cutting and bagging operations, operations such as sealing are usually performed during non-feeding cycles of the machine. Similar to the sealing process, cutting and bagging operations also determine the best machine form. In addition to these basic functions, the execution of additional operations such as zippers, perforated bags, totes, vandal-resistant seals, pouches, and crown treatments may depend on the design of the packaging bag. Attachments attached to the base machine perform such additional operations.